Demos

(INTEGRATION OF FUNCTIONS AND DEVICES TO EDGE CLOUD SERVICES)

September 2020 - September 2023

Demos

TANDEM Robotics Use Case

The robot is controlled by the TANDEM system and serves as a node of the system’s edge. Using TANDEM, we compose and send different tasks for execution by the robot. Four collaborative robotic services were developed, which were registered in the TANDEM service catalog. These services are combined using TANDEM’s Service Chain Orchestrator to create two different scenarios. The first scenario includes visual quality control of final products using artificial intelligence, followed by grabbing and placing the objects in a suitable position, thus simulating the functionality of the robot in an industrial production line. In the second scenario, the robot separates types of pharmaceutical packaging. The steps are the following:

- Registration of Object Detection Model Training Service: After creating the object detection model training and retraining service, we register it in the TANDEM platform. This service allows the user to input their own set of images, based on which machine learning model training takes place, as well as the ability for automatic performance evaluation of the model, according to the user’s specifications.

- Registration of Robot as a TANDEM Node: The second step is to integrate the robot’s computer as a node of the TANDEM platform. This will provide the capability for immediate start of robot services, as well as direct communication of the robot with other TANDEM nodes.

- Registration of the Hardware Controller Service: After making the robot a TANDEM node, we register the basic services that make up our scenario. The first service is the Hardware Controller. This service ensures the connection between the devices that make up the robot (arm and sensors) and the other services of the scenario. Specifically, the Hardware Controller always runs on the robot’s computer and contains the programs (drivers) of the robot’s actuators and sensors.

- Registration of the Motion Planning Service: Next, we register the Motion Planning service in the TANDEM platform. This service contains the necessary software and libraries to calculate the valid path the arm should follow based on the desired final position of the arm.

- Registration of the Object Detection Service (for quality control of beverage packaging): The third service we register in TANDEM is the object detection service. To create this service, we have used the Object Detection Model Training Service mentioned above, to get the appropriate machine learning model, specifically trained for our scenario. In our case, the Object Detection Service distinguishes between useful and defective beverage cans (of a specific brand) and returns the appropriate estimation and the position of the detected object in the image.

- Registration of the Pick and Place Service: In this step, we register the Pick and Place service, which completes the first use scenario of the robot. This service implements the logic of the scenario, such as processing the images read by the robot’s camera, calculating the position of the objects, and the successive commands that must be given to the arm for task execution.

- Creation of Products from the above services and selection of the robot node for their execution.

- Creation of the “Identification of Defective Beverage Packaging” Service Chain for the Robot: Having registered all the individual services/products, we create a service chain (Service Chain) to implement the overall scenario. In the first robotic scenario, after taking the image from the robot’s camera, we get the positions and classes of the objects (which will be indicated by the object recognition service), and use the arm to place each object in the predetermined place according to whether it is defective or useful.

- Start of Robot Service Chain 1 “Identification of Defective Beverage Packaging”: At this stage, we start the service chain from the TANDEM platform, and see all the individual services starting in real-time, both those starting on the robot’s computer and on other local servers for computational resource sharing.

- Registration of Object Detection Service for Separation of Pharmaceuticals: To highlight the flexibility of the platform and the speed of changing the robot’s task, we will register another service, with the aim of changing the robot’s task in real-time. Specifically, we have a second object detection service, which separates pharmaceutical packaging, instead of beverage packaging. Creation of a product from this service and selection of the robot node for its execution.

- Start of Robot Service Chain 2 “Separation of Pharmaceutical Packaging”: In this step, by making a simple modification in the service chain we have created from the Service Chain Orchestrator of TANDEM, we replace the existing service (separation of beverage packaging) with the new one (separation of pharmaceutical packaging).

- Start of the New Service Chain: Having created the new service chain in the previous step, we terminate the previous one and put it into operation. This demonstrates the easy, rapid, and physically inaccessible change of the robot’s operational goal through the TANDEM platform.

- Selection of Central Node (instead of the robot) for Execution of the Object Recognition Service. Restart of the New Service Chain.

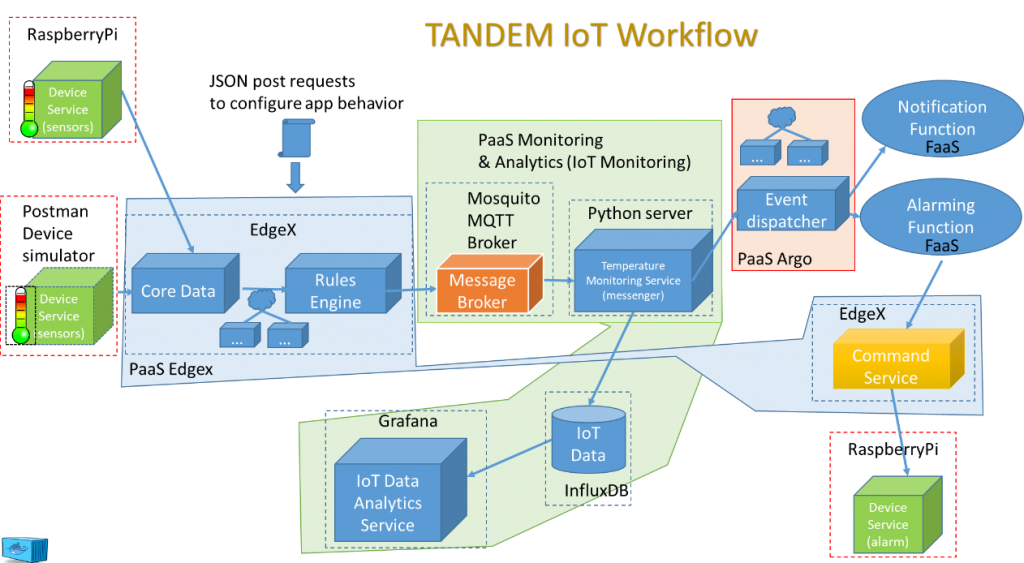

TANDEM IoT Workflow

Initially in “Tandem IoT Workflow” all the installation and management phases of the services that are necessary for the TANDEM nodes operations are presented. Then, all the installation steps for both the core TANDEM Platform as a Service (PaaS) services, such as EdgeX, as well as for the installation and support of an end-to-end IoT scenario as a custom TANDEM PaaS service are listed. In both cases the π-Edge platform is used for the installation of the PaaS services, which is characterized as edge platform manager). Through the specific IoT (custom) TANDEM PaaS service, both the visualized humidity and temperature measurements collected from the sensors of a RasberryPi connected to the EdgeΧ PaaS service, as well as the mechanisms triggered (“alarm” and “notification”) when the specific measurements exceed the expected upper bounds are depicted. Specifically, for the triggering mechanisms (“alarm” and “notification”) we present in detail how the appropriate Argo Function as a Service (FaaS) services and the actions they implement are created, both for the sending of a notification email in case of “notification” mechanism, and for the RasberryPi’s alarm activation in case of the “alarm” mechanism.

INTRACOM TELECOM (INTRACOM S.A. TELECOM SOLUTIONS)

19.7 km Markopoulou Ave., Peania Athens, Greece, 19002

Tel.: +30-210-66 71 000 / Fax: +30-210-66 71 001

E: info@intracom-telecom.com

Intracom S.A. Telecom Solutions (INTRACOM TELECOM Α.Ε. ΤΗΛΕΠΙΚΟΙΝΩΝΙΑΚΩΝ ΛΥΣΕΩΝ)

19,7 χλμ. Λεωφ. Μαρκοπούλου, Παιανία Αττικής, Ελλάδα, 19002

Tel.: +30-210-66 71 000 / Fax: +30-210-66 71 001

Ε: info@intracom-telecom.com